Author: Tim Scott, Head of Sales, Condair plc

Cool humidification

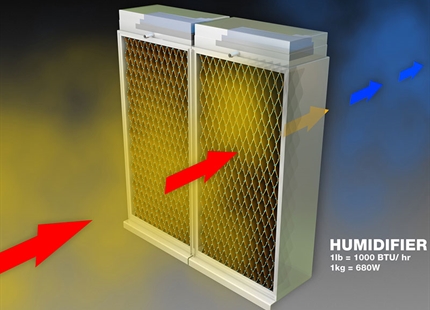

A cold water humidifier evaporating 100kg of water per hour to an atmosphere will provide approximately 63kW of adiabatic cooling and it will do this while running on less than 0.3kW of electricity.

Cooling an atmosphere by using the adiabatic effect of evaporating water from a humidifier is far more energy efficient, and therefore cost effective, than using compressor driven mechanical cooling. In fact the running costs can be up to 80% less.

That is not to say evaporative cooling can replace compressor driven cooling, as the effectiveness is dependent on the temperature and humidity of the air being introduced to the humidifier. Warm dry air is able to absorb more moisture, and therefore have a greater capacity to be cooled, than cold humid air, which cannot absorb as much.

Evaporative cooling is therefore most effective at certain times of year or with certain applications where there is a large heat gain in the space to be cooled. By working alongside a mechanical cooling system, a cold water humidifier can help reduce the required operation of the mechanical chiller with a reduction in the overall cooling system’s energy consumption and costs.

Types of cooler

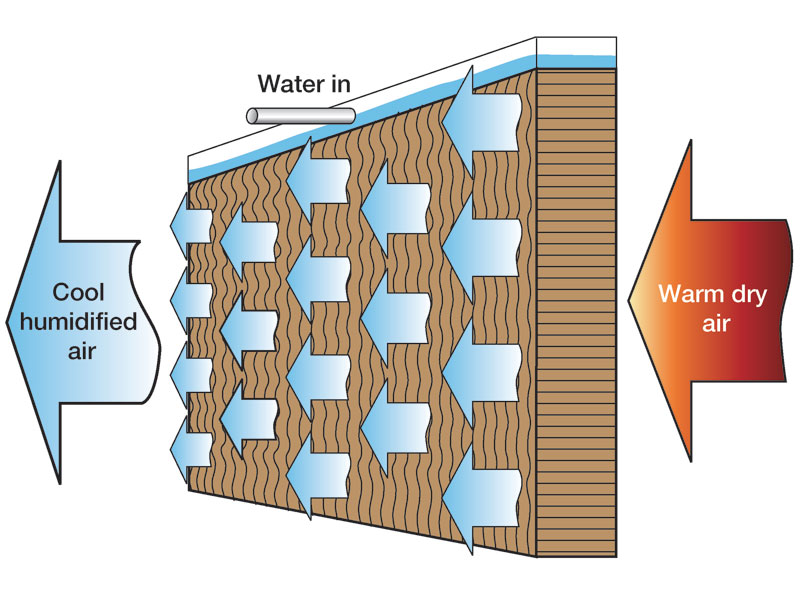

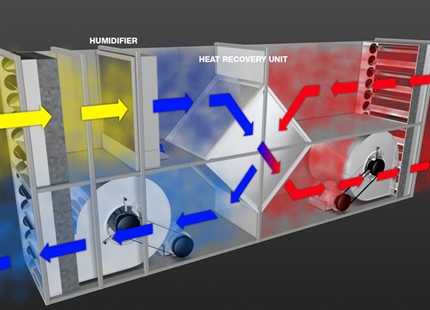

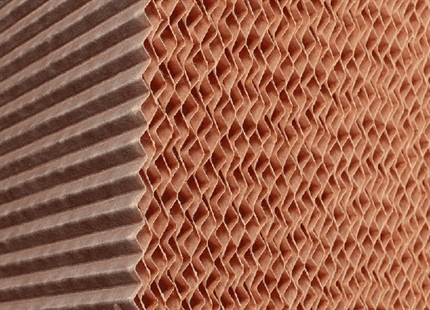

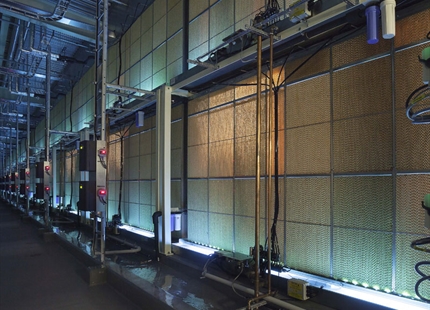

There are two main types of cold water humidifier and two main ways to cool using them. Firstly, the humidifier types are either evaporative or spray. An evaporative humidifier, such as the Condair ME, is located in a duct or air handling unit. Air flows through a continually moistened evaporative matrix and absorbs moisture as it does so. This evaporation can cause a drop in the air temperature of up to 12°C.

A spray humidifier will either use compressed air or high pressure to atomise the water into the air stream, again with the same adiabatic cooling effect. The decision as to which type of cold water humidifier to use in evaporative cooling applications will be determined by a number of factors including, size and geometry of air handling unit, level of control required, water hardness and evaporation load.

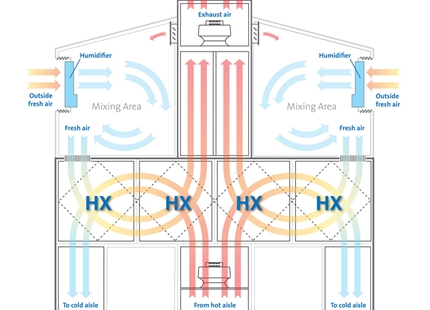

These humidifiers can be employed on the incoming air as well as the exhaust air to provide cooling. By using the humidifier on the incoming air, a direct cooling effect is achieved. The amount of cooling depends on the outside air’s temperature and humidity so this technique is most used during the warmer months in a UK climate.

This form of cooling has been widely employed recently in data centres alongside “Free Air Cooling” systems. By bringing in fresh air to provide cooling rather than conditioning and re-circulating internal air, data centres can operate without mechanical cooling for up to 70% of the year. However, when used in conjunction with an evaporative cooling humidifier, the window of operation for a free air cooling system can be extended to 95% of the year. This means the mechanical chillers are only required to operate on the very hottest days.

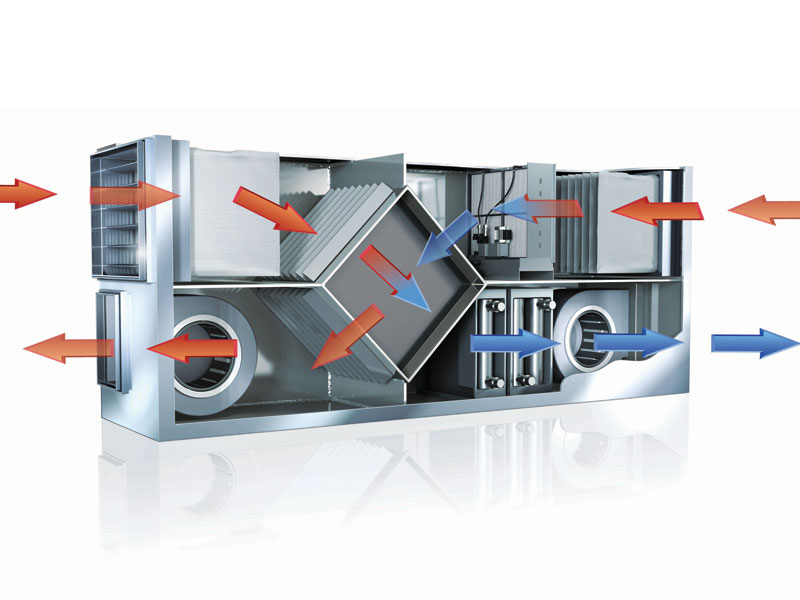

Exhaust air heat recovery

Exhaust air from a ventilation system can often be used to cool the incoming air with the use of a heat exchanger. If an evaporative humidifier is located in the exhaust air prior to the heat exchanger, the exhaust air can be humidified towards saturation point, reducing the exhaust air temperature significantly.

This type of exhaust air cooling can be used in general offices or public buildings as well as in manufacturing applications.

Humidification benefits

Alongside the benefits of low cost cooling, adiabatic humidifiers also offer all the benefits of correct humidity control. For offices and public premises that means a healthy atmosphere that doesn’t dehydrate employees, promote dust and airborne infections or cause static electrical issues. Adiabatic humidifiers also do this at a fraction of the operating costs compared to electric steam humidifiers.

A typical electric steam humidifier providing 100kg per hour of moisture to an air handling unit, operating for an equivalent of 1,129 hours per year at full output would consume around 84,643kWh of electricity annually. An adiabatic humidifier providing the same output would use just 553kWh, which is less than 1% of an electric steam humidifier’s consumption.

Some applications that only require humidification and don’t want the associated cooling that cold water humidifiers provide can integrate pre-heating into the air handling unit to counteract the humidifier’s cooling effect. As gas is often used for pre-heating, cold water humidifiers with gas pre-heating still offer substantial savings in terms of cost and carbon footprint when compared to electric steam humidifiers due to the economy of gas over electricity.

As end users strive to reduce energy costs and the carbon footprint associated with their business, more and more cold water humidifiers are being employed to provide low cost, environmentally friendly cooling and humidification. As designers, consultants and air handling unit manufacturers explore the possibilities of adiabatic cooling this is likely to increase further.